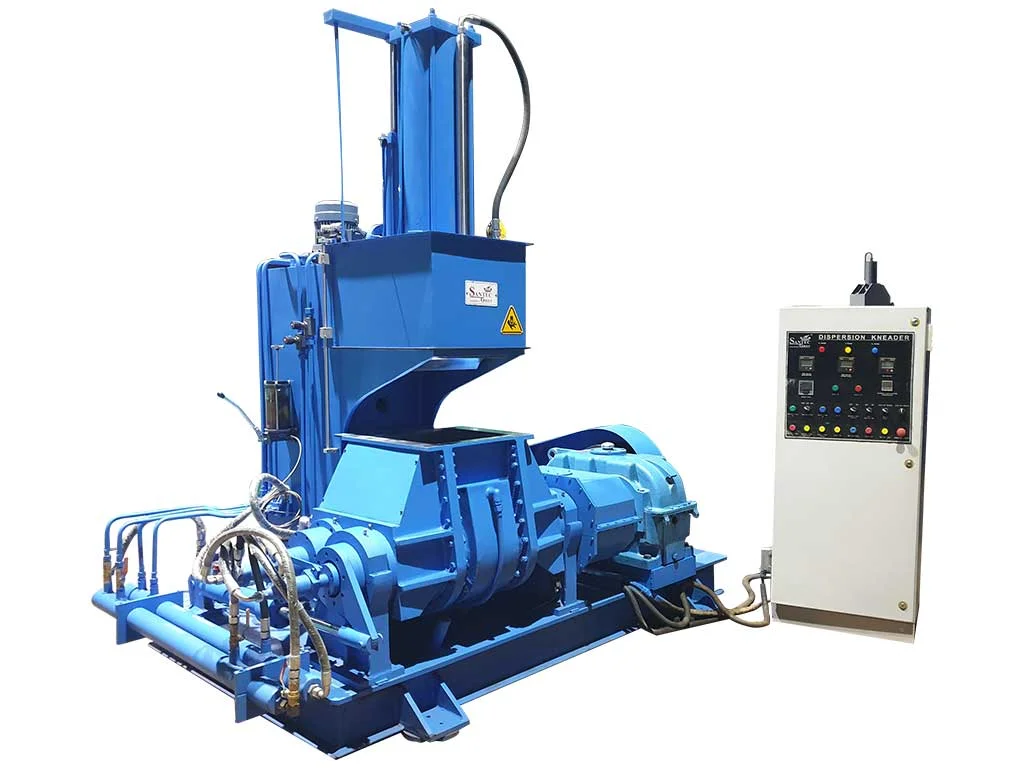

Product Overview of Two Rolls Mixing Mills, Stock Blenders & Auto Blenders

Two-roll mixing mills, Stock Blenders, and Auto Blenders are essential equipment for the rubber and plastic industry, widely used in compounding, mixing, and blending processes. These machines ensure the efficient mixing of rubber compounds, providing superior dispersion, consistency, and precision. Designed with advanced engineering, they deliver excellent durability, productivity, and ease of use, making them an indispensable solution for modern manufacturing setups.

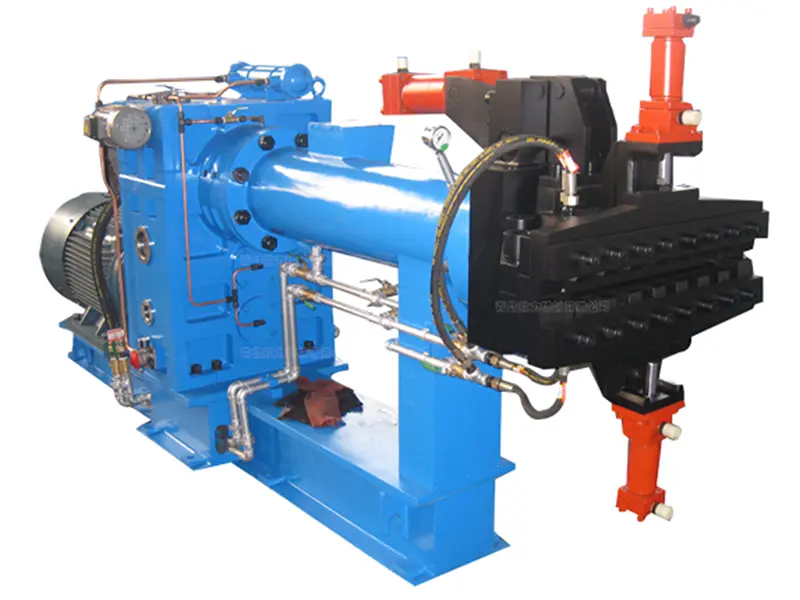

Two Rolls Mixing Mills

Two Two-roll mixing Mills are the backbone of rubber compounding. They consist of two horizontally placed rolls that rotate toward each other, creating shear and pressure to mix and refine raw materials. They are widely used for preparing rubber sheets, mixing natural and synthetic rubber, and performing trial blends in laboratory and production setups.

Stock Blenders

Stock Blenders are mounted on Two Roll Mills to ensure continuous feeding of stock to the rolls. They improve the consistency of mixing by redistributing the stock evenly. This not only enhances dispersion but also reduces operator fatigue and minimizes batch variation, ensuring uniform compound quality.

Auto Blenders

Auto Blenders are advanced blending systems designed to reduce human intervention while improving productivity. By automating the blending process, these machines help reduce errors, increase throughput, and ensure repeatable quality. They are especially valuable for industries where precision and speed are critical factors.

Applications

These machines are widely used in the manufacturing of rubber products, automotive components, footwear, belts, hoses, and various industrial rubber goods. Their robust performance and adaptability make them suitable for both small-scale and large-scale production facilities.

About Santec Group

Santec Group, based in Delhi, India, is a leading manufacturer and supplier of Two-Roll Mixing Mills, Stock Blenders, and Auto Blenders. With years of expertise and advanced manufacturing facilities, the company has established itself as a trusted name in the rubber and plastic machinery industry. Santec focuses on delivering world-class machines that combine innovation, durability, and energy efficiency. By supplying cutting-edge equipment, the company continues to empower industries with solutions tailored to meet global standards.

Two Rolls Mixing Mills Stock Blanders Auto Blenders

Precision Engineered Hydraulic Press Solutions — Powering Performance, Productivity & Perfection.

Available in Delhi

₹450,000.00 / Per piece

Inclusive of all taxes

Established in 1998, Santec Group has grown into a globally trusted leader in hydraulic press manufacturing and industrial automation solutions.

Leading Manufacturer And Supplier in India

- Heavy-duty construction for long-lasting durability.

- Advanced safety features for operator protection.

- High-precision rolls for superior mixing.

- Energy-efficient design with reduced power consumption.

- Low maintenance requirements with reliable performance.

Contact Product Information:

Call us for detailed product information, customization options, and bulk pricing.

Product Description

Technical Specifications

| Roll Sizes | 6” x 13” to 26” x 84” (custom options available) |

| Roll Material | Chilled cast iron with hardness 500 – 520 BHN |

| Friction Ratio | 1:1.25 to 1:1.4 (adjustable) |

| Motor Power | 10 HP to 200 HP |

| Stock Blender | Pneumatically operated, with linear reciprocating arms |

| Auto Blender | Fully automated PLC-controlled system |

| Speed | Variable speed drive options available |

| Safety | Emergency stop, overload protection, and safety guards |

| Cooling/Heating | Steam, water, or oil circulation systems |

Product Benefits

-

Ensures uniform compound mixing.

-

Reduces manual effort with stock/auto blending.

-

Enhances productivity and output consistency.

-

Provides flexibility for a wide range of rubber compounds.

-

Increases safety and reduces workplace hazards.

-

Saves energy with efficient motor systems.

-

Minimizes operator fatigue.

-

Offers scalability for small and large industries.

-

Delivers reliable and repeatable results.

-

Long service life ensures better ROI.

Quality Assurance

Every product undergoes rigorous quality checks and comes with comprehensive warranty coverage.

Frequently Asked Questions

For mixing, sheeting, and refining rubber compounds.

Yes, they ensure uniformity and reduce operator effort.

Yes, they are versatile and adaptable.

Emergency stops, overload protection, and safety guards.

Yes, Santec offers tailor-made solutions.

Based in Delhi, India.

Rubber, plastic, automotive, footwear, and industrial goods.

Yes, globally across multiple continents.

Over two decades of experience.

Yes, with installation, training, and maintenance support.

Starting at ₹4,50,000/- (approx.).

With proper maintenance, over 15–20 years.

Depends on model; ranges from 10 HP to 200 HP.

Yes, models are available for both small and large setups.

Generally 6–8 weeks, depending on customization.