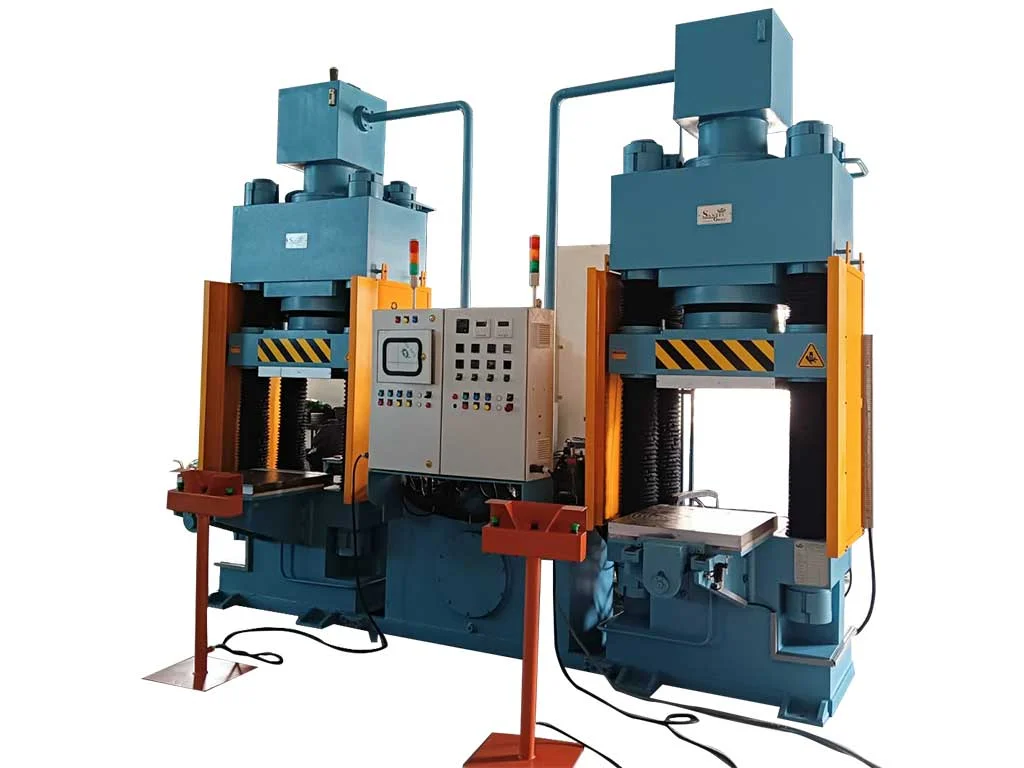

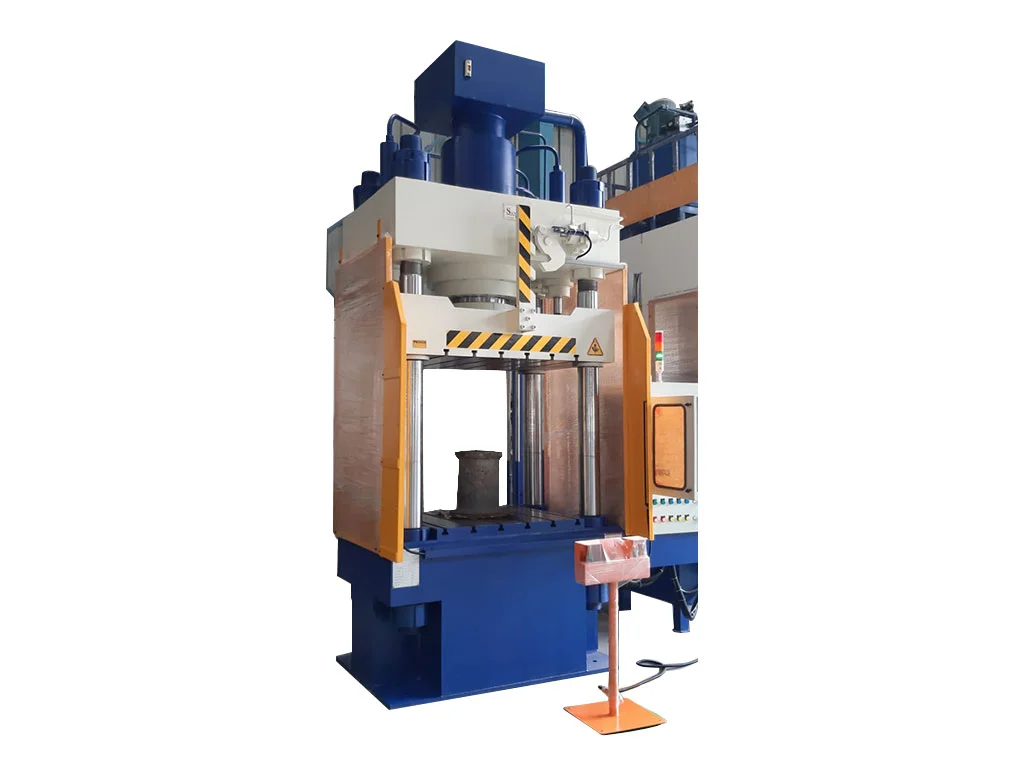

Product Overview of SMC Compression Moulding Press Machine

The SMC Compression Moulding Press Machine is a state-of-the-art equipment widely used in industries for manufacturing high-quality Sheet Moulding Compounds (SMC) products. Known for its robust design, precision engineering, and high productivity, this press is the backbone of several sectors, including automotive, electrical, and construction. With increasing demand for lightweight and durable materials, SMC moulding machines play a vital role in modern manufacturing.

What is an SMC Compression Moulding Press Machine?

Sheet Moulding Compound (SMC) is a fiber-reinforced composite material recognized for its strength, heat resistance, and lightweight properties. An SMC Compression Moulding Press Machine is designed to mould this compound into a variety of components under high pressure and controlled temperature. This machine ensures uniform molding, reduces cycle time, and achieves a superior product finish, making it the first choice for industries that prioritize both quality and efficiency.

Applications of the Machine

The machine is highly versatile and used in multiple industries, including:

* Automotive industry – manufacturing lightweight panels, bumpers, and structural components.

* Electrical industry – creating switchgear components, insulators, and housings.

* Construction – durable roofing sheets, water tanks, and infrastructure materials.

* Aerospace – lightweight, strong, and durable interior and exterior panels.

Advantages of Using an SMC Compression Moulding Press

Investing in this machine enables companies to achieve higher accuracy, minimize waste, and ensure repeatable quality. Its advanced hydraulic system, precision temperature control, and user-friendly design make it ideal for mass production. Additionally, its eco-friendly operation reduces energy consumption and improves sustainability in production processes.

About Santec Group Corporation in Delhi

Santec Group Corporation is one of the leading manufacturers and suppliers of SMC Compression Moulding Press Machines in Delhi. With years of expertise in the field of hydraulic and industrial presses, the company has established itself as a trusted brand for high-quality, durable, and innovative machines. Santec not only focuses on delivering reliable equipment but also provides exceptional after-sales support, ensuring long-term customer satisfaction. Buyers in Delhi and across India can purchase their SMC Compression Moulding Press Machines from Santec at the best market price, customized as per client requirements.

SMC Compression Moulding Press Machine

Precision Engineered Hydraulic Press Solutions — Powering Performance, Productivity & Perfection.

Available in Delhi

₹450,000.00 / Per piece

Inclusive of all taxes

Established in 1998, Santec Group has grown into a globally trusted leader in hydraulic press manufacturing and industrial automation solutions.

Leading Manufacturer And Supplier in India

- Heavy-duty, robust frame for long-lasting performance.

- Advanced hydraulic system for smooth and consistent operation.

- Precision temperature and pressure control for uniform molding.

- User-friendly interface with digital control options.

- Customizable tonnage capacity as per client needs.

Contact Product Information:

Call us for detailed product information, customization options, and bulk pricing.

Product Description

Technical Specifications

| Tonnage Capacity | 50 – 2000 Tons |

| Platen Size | 400 mm × 400 mm to 3000 mm × 3000 mm |

| Daylight Opening | 200 mm – 3000 mm |

| Stroke Length | 200 mm – 2500 mm |

| Heating System | Electrical / Steam / Oil-heated platens |

| Control System | PLC-based or manual control |

| Cycle Time | Adjustable, 30 – 180 seconds |

| Power Supply | 3 Phase, 415V, 50 Hz |

| Cooling System | Water/Oil cooling options available |

| Customization | Available as per application |

Product Benefits

-

Enhanced product quality and durability.

-

Faster cycle time and increased productivity.

-

Reduced raw material wastage.

-

Energy-efficient operation.

-

Suitable for a wide range of industries.

-

Easy maintenance and long service life.

-

Accurate molding of complex shapes.

-

Cost-effective manufacturing solution.

-

Environmentally friendly process.

-

Reliable after-sales support from Santec.

Quality Assurance

Every product undergoes rigorous quality checks and comes with comprehensive warranty coverage.

Frequently Asked Questions

It is used for molding sheet moulding compounds into durable and lightweight industrial components.

Santec offers machines from 50 tons up to 2000 tons, based on customer needs.

Yes, it can accurately mold complex designs with precision.

Yes, heating systems include electrical, steam, or oil-based platens.

Yes, Santec provides tailor-made machines to suit industry-specific requirements.

The company is based in Delhi, India.

Santec has decades of experience in manufacturing industrial and hydraulic presses.

Yes, Santec provides installation, training, and after-sales service.

Yes, Santec ensures prompt availability of genuine spare parts.

Yes, demo and consultation services are available on request.

The starting price is around ₹4,50,000/- depending on capacity and customization.

SMC is widely used in automotive, electrical, aerospace, and construction industries.

Compression moulding uses pressure and heat to form materials, while injection moulding injects molten material into molds.

With proper maintenance, it can last 15–20 years.

Yes, Santec provides cost-effective options suitable for both small and large industries.