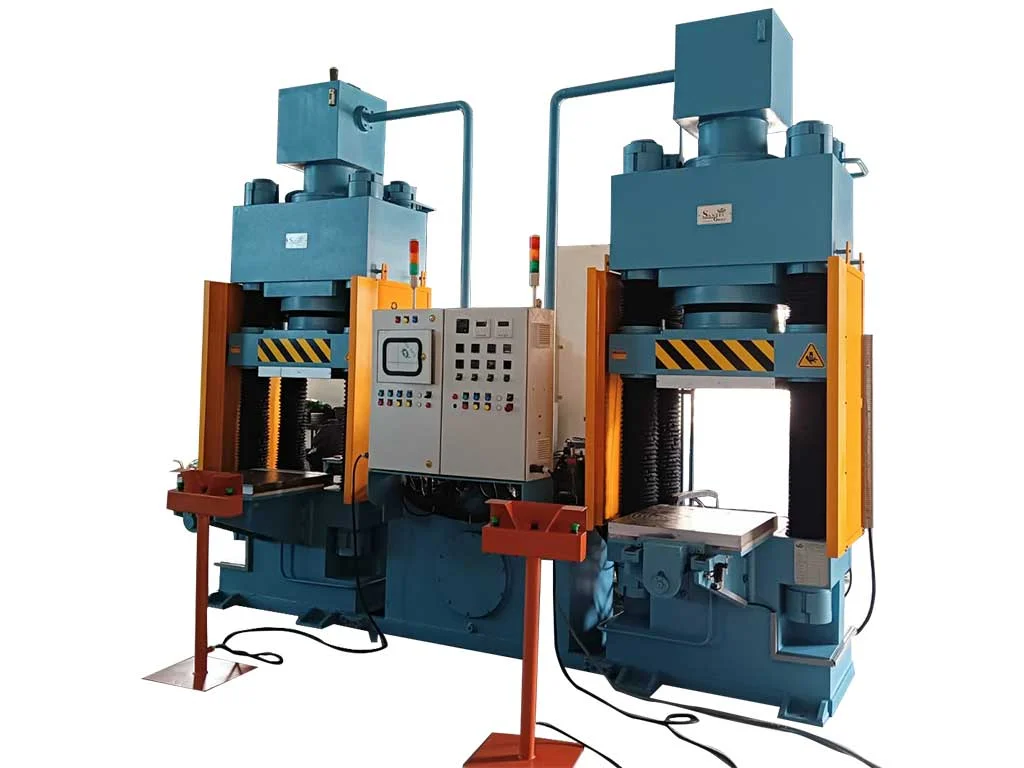

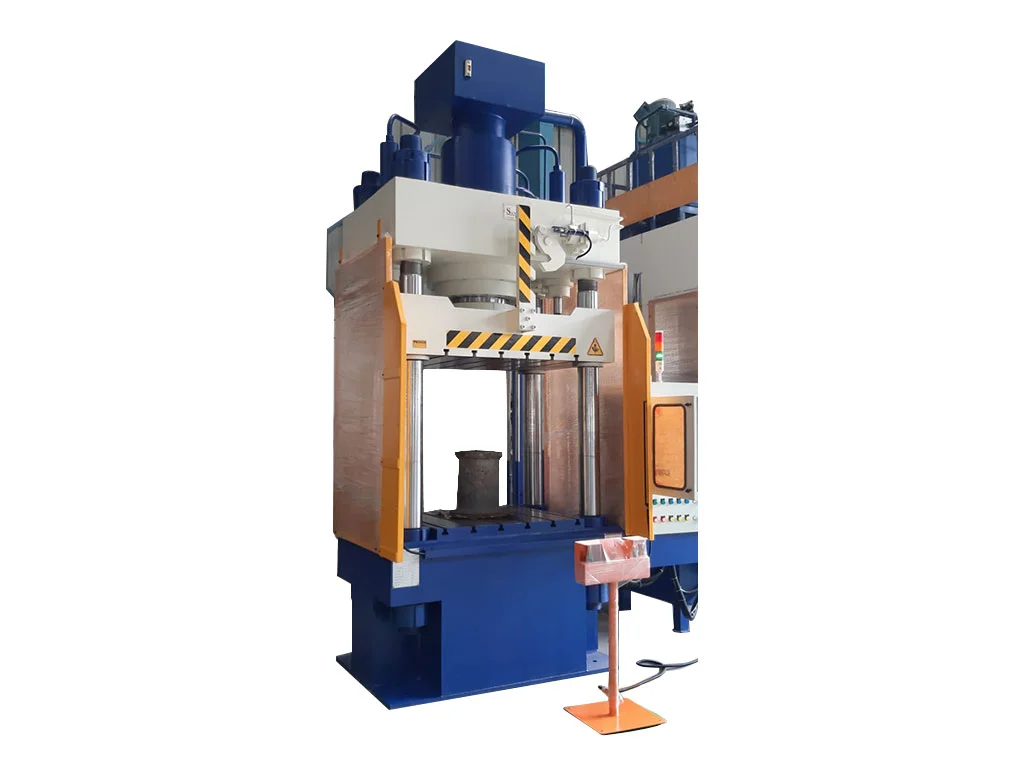

Product Overview of Precured Tread Moulding Presses

The tire retreading industry requires highly reliable, durable, and efficient machines to ensure consistent results. Among the various pieces of equipment used, the Precured Tread Moulding Press plays a crucial role in shaping and curing precured treads for retreaded tires. These machines are designed for heavy-duty performance and are essential for manufacturers and service providers dealing with tire retreading.

What is a Precured Tread Moulding Press?

A Precured Tread Moulding Press is specialized equipment used to mould precured tread rubber onto worn-out tires, thereby extending their lifespan. This process enhances grip, performance, and safety while reducing the cost of new tire purchases. These presses are widely used in the automotive, transportation, and fleet industries, where retreading is a cost-effective and eco-friendly solution.

Why Choose a Precured Tread Moulding Press?

The primary advantage of these machines is their precision and uniformity. They allow operators to achieve a high-quality finish that matches the strength and performance of new tires. Their durability ensures years of service, while their user-friendly controls make them suitable for both small and large-scale retreading facilities.

Applications in Industry

Precured Tread Moulding Presses are extensively used in:

* Tire retreading workshops

* Transport and logistics companies

* Fleet management service providers

* Rubber product manufacturers

These applications underscore their importance in reducing costs, extending tire life, and promoting sustainable business practices.

About Santec Group Corporation – Delhi’s Trusted Manufacturer

Santec Group Corporation, based in Delhi, is one of the leading manufacturers and suppliers of Precured Tread Moulding Presses. Known for their engineering excellence, Santec designs machines that deliver superior performance, high efficiency, and unmatched durability. Their machines are built with advanced technology and meet global standards. Customers across India trust Santec for cost-effective solutions and exceptional after-sales service.

Precured Tread Moulding Presses

Precision Engineered Hydraulic Press Solutions — Powering Performance, Productivity & Perfection.

Available in Delhi

₹1,200,000.00 / Per piece

Inclusive of all taxes

Established in 1998, Santec Group has grown into a globally trusted leader in hydraulic press manufacturing and industrial automation solutions.

Leading Manufacturer And Supplier in India

- Heavy-duty frame for long-lasting performance

- Advanced hydraulic system for smooth operation

- Precision heating and pressure control

- User-friendly controls with safety mechanisms

- Energy-efficient design to reduce operating costs

Contact Product Information:

Call us for detailed product information, customization options, and bulk pricing.

Product Description

Technical Specifications

| Type | Hydraulic Precured Tread Moulding Press |

| Press Capacity | 50 – 200 Tons (customizable) |

| Heating System | Electrical / Steam heating |

| Temperature Range | Up to 250°C |

| Platen Size | Customizable as per requirement |

| Hydraulic Power Pack | High-efficiency motor-driven |

| Control Panel | PLC-based with digital display |

| Safety Features | Emergency stop, overload protection |

| Construction | Heavy-duty welded steel frame |

| Operation | Semi-automatic / Automatic options available |

Product Benefits

-

Extends tire life significantly

-

Cost-effective compared to buying new tires

-

Improves tire safety and performance

-

Eco-friendly retreading solution

-

Reduces operating costs for fleet owners

-

Increases productivity in retreading workshops

-

High accuracy ensures uniform tread bonding

-

Reliable and low-maintenance equipment

-

Suitable for both small and large-scale operations

-

Long operational life ensures high return on investment

Quality Assurance

Every product undergoes rigorous quality checks and comes with comprehensive warranty coverage.

Frequently Asked Questions

It is used to mould precured tread rubber onto old tires, extending their life.

Yes, it can be customized for different tire sizes and applications.

Power consumption depends on the model and capacity, but it is designed for energy efficiency.

With proper maintenance, it can last for over 15–20 years.

Basic training is enough, as the machine comes with user-friendly controls.

The company is headquartered in Delhi, India.

Yes, the company offers installation and training support.

Santec serves automotive, tire retreading, transport, and rubber industries.

Yes, Santec exports its equipment to several international markets.

The company provides maintenance, spare parts, and technical assistance.

Tire retreading is a process where worn tires are given a new tread, making them reusable.

Yes, retreaded tires perform almost like new tires when manufactured properly.

Retreading can save up to 50–60% of the cost of buying new tires.

Depending on the condition of the casing, a tire can be retreaded 2–3 times.

Yes, retreading reduces waste and conserves natural resources, making it highly eco-friendly.