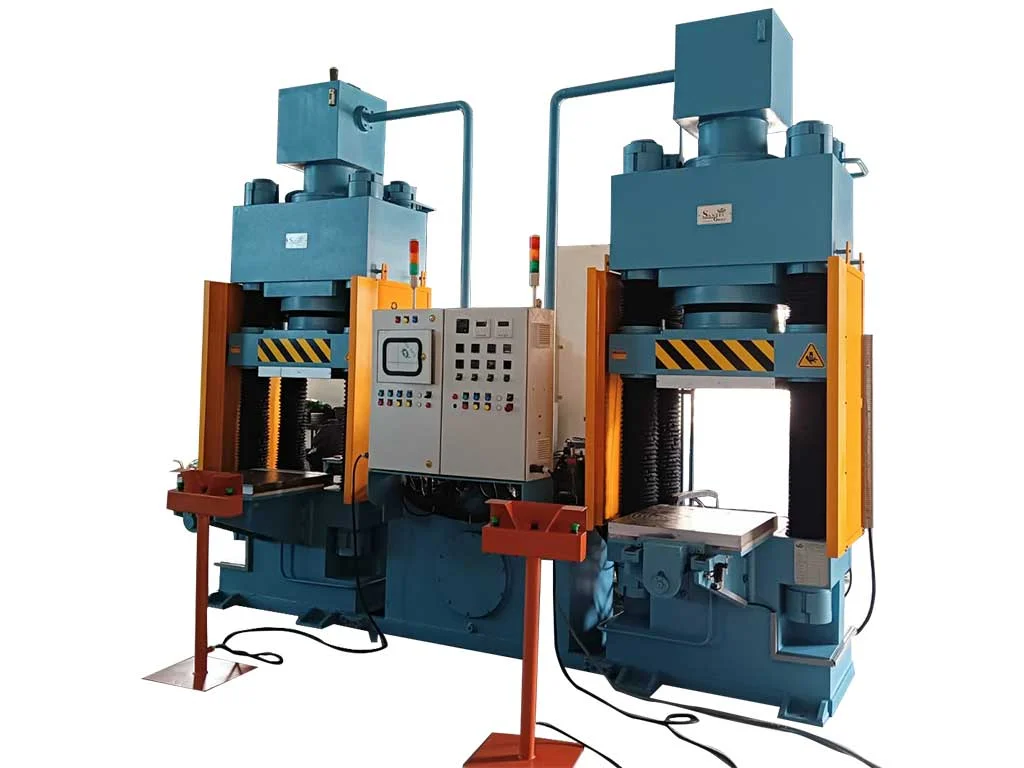

Compression Moulding Presses (Downstroking Type) – Product Overview

Introduction

Compression molding presses deliver precise shaping, saving manufacturers time and material while improving part quality and consistency. The Downstroking Type excels in maintaining consistent pressure and accuracy, resulting in reduced defects and less downtime for production lines.

---

What is a Downstroking Type Compression Moulding Press?

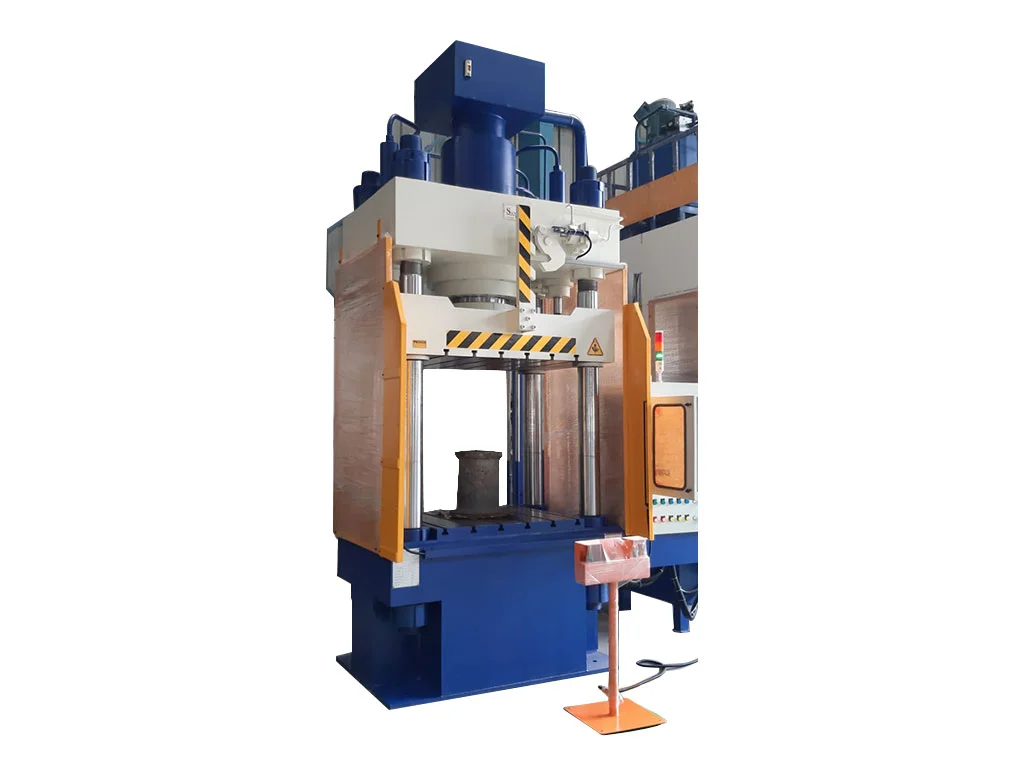

A downstroking compression moulding press excels by driving the ram (platen) downward, powerfully compressing the material within the mould cavity. This precise action delivers controlled pressure and heat, ensuring extraordinary product consistency. Trusted across automotive, aerospace, electrical, and consumer goods sectors, these presses empower businesses to achieve superior results.

---

Why Choose a Downstroking Type Press?

Select the downstroking press to minimize product defects, enhance worker safety, and achieve faster, more efficient cycles with precise temperature control, resulting in higher production quality and fewer interruptions.

---

Applications of Compression Moulding Presses

* Automotive parts (seals, gaskets, brake components)

* Aerospace composites

* Electrical insulators and switchgear components

* Rubber and plastic products

* Consumer goods and industrial equipment

About Santec Group Corporation – Delhi

Santec Group Corporation ensures improved productivity and reliability with durable presses engineered for minimal downtime. Customers benefit from cost-effective solutions tailored to evolving manufacturing needs and enjoy robust support throughout the machine’s life cycle.

With Santec, you receive proven press reliability, responsive support, and immediate cost savings, ensuring your investment delivers maximum value and operational peace of mind.

Compression Moulding Presses Downstroking Type

Precision Engineered Hydraulic Press Solutions — Powering Performance, Productivity & Perfection.

Available in Delhi

₹450,000.00 / Per piece

Inclusive of all taxes

Established in 1998, Santec Group has grown into a globally trusted leader in hydraulic press manufacturing and industrial automation solutions.

Leading Manufacturer And Supplier in India

- Hydraulic downstroking system for uniform pressure application.

- Heavy-duty welded steel frame ensuring stability.

- Advanced temperature control system for precise moulding.

- PLC-based control panel for easy operation.

- Customizable tonnage capacity and platen size.

Contact Product Information:

Call us for detailed product information, customization options, and bulk pricing.

Product Description

Technical Specifications

| Type | Downstroking Hydraulic Compression Moulding Press |

| Capacity | 50 – 2000 tons |

| Platen Size | 400 mm x 400 mm to 1500 mm x 1500 mm |

| Daylight Opening | 200 mm to 1000 mm |

| Stroke Length | 150 mm to 800 mm |

| Heating System | Electrical/Steam/Oil heating |

| Control | PLC or Manual Push Button |

| Power Supply | 415V, 3 Phase, 50Hz |

| Frame Construction | Heavy-duty welded steel |

Product Benefits

-

Ensures consistent product quality.

-

High durability and low maintenance.

-

Energy-efficient operation.

-

Suitable for a wide range of materials.

-

Enhances productivity and reduces cycle time.

-

Operator-friendly controls.

-

Minimizes wastage of raw material.

-

Safe and reliable performance.

-

Long operational life.

-

Affordable pricing with high ROI.

Quality Assurance

Every product undergoes rigorous quality checks and comes with comprehensive warranty coverage.

Frequently Asked Questions

Rubber, thermosetting plastics, composites, and more.

From 50 tons to 2000 tons, depending on requirement.

Yes, it can be equipped with advanced PLC controls.

Yes, Santec offers customized platen sizes.

Automotive, aerospace, electrical, and consumer goods industries.

The company is headquartered in Delhi, India.

Yes, Santec exports to multiple international markets.

The company has decades of experience in hydraulic press manufacturing.

Yes, installation support and operator training are provided.

Absolutely, Santec has a strong after-sales service network in Delhi and beyond.

A hydraulic machine used to shape materials under heat and pressure.

In downstroking presses, the ram moves downward, while in upstroking, it moves upward.

Starting from ₹4,50,000/- onwards depending on capacity and customization.

Yes, hydraulic presses provide consistent pressure and flexibility.

Consider tonnage, platen size, material, and application needs.