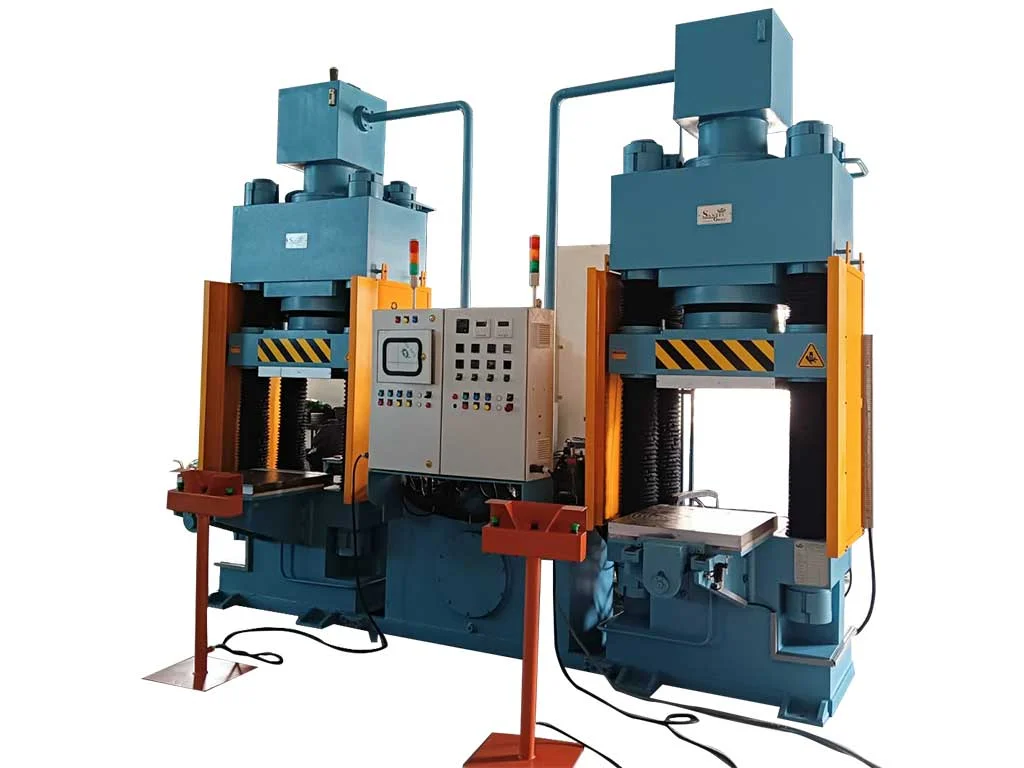

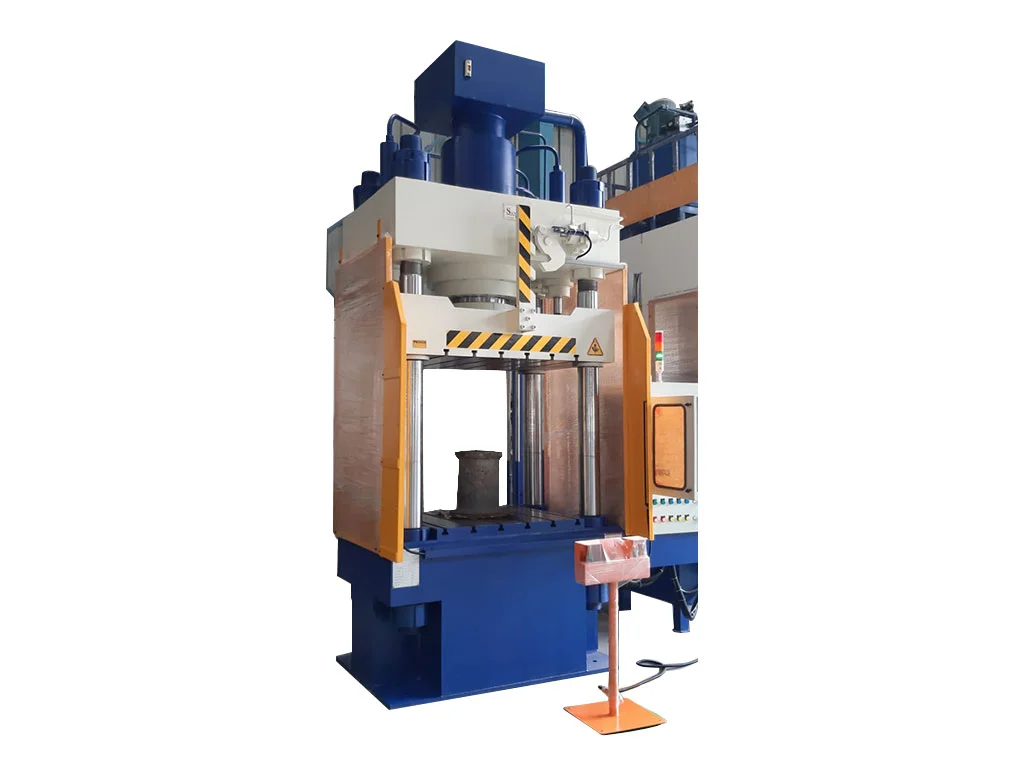

Vacuum Compression Moulding Presses – Product Overview

Vacuum Compression Moulding Presses are advanced industrial machines designed to meet the high demands of precision moulding in various sectors, including automotive, aerospace, rubber, plastics, and composites. These presses combine heat, pressure, and vacuum to produce flawless, moulded parts without air entrapment, ensuring high-quality output and longer product durability.

---

What is a Vacuum Compression Moulding Press?

A Vacuum Compression Moulding Press operates under vacuum, reducing defects such as voids and bubbles while improving strength, finish, and consistency.

---

Why Choose a Vacuum Compression Moulding Press?

These presses are highly recommended for industries where precision and strength are critical. By combining vacuum technology with compression, these presses are ideal for use in industries where precision and strength are crucial. Vacuum and compression ensure uniform mould filling. plastic components.

* Electrical sector: Insulators and connectors.

* Aerospace industry: Composite structural parts.

* Defense: High-strength moulded parts.

* Medical equipment: Precision rubber moulding.

---

About Santec Group Corporation – Cochin

Santec Group Corporation in Cochin manufactures and supplies Vacuum Compression Moulding Presses, known for high performance and cost-effectiveness. Customers can buy directly from the supplier for reliable industrial machinery.

Vacuum Compression Moulding Presses

Precision Engineered Hydraulic Press Solutions — Powering Performance, Productivity & Perfection.

Available in Cochin

₹750,000.00 / Per piece

Inclusive of all taxes

Established in 1998, Santec Group has grown into a globally trusted leader in hydraulic press manufacturing and industrial automation solutions.

Leading Manufacturer And Supplier in India

- Heavy-duty rigid frame construction.

- Advanced vacuum chamber with precise sealing.

- Fully automatic/ semi-automatic operation.

- PLC-based control system for accuracy.

- Energy-efficient hydraulic system.

Contact Product Information:

Call us for detailed product information, customization options, and bulk pricing.

Product Description

Technical Specifications

| Tonnage Capacity | 30 to 2000 Tons |

| Daylight Opening | 400 mm to 1200 mm |

| Platen Size | 400 x 400 mm up to 2000 x 2000 mm |

| Stroke Length | 200 mm to 1000 mm |

| Heating System | Electric / Steam / Thermal Oil |

| Vacuum System | High-efficiency chamber with pump |

| Controls | PLC / HMI Touch Screen with automation options |

| Cooling System | Optional water circulation |

| Power Supply | 415 V, 3 Phase, 50 Hz |

Product Benefits

-

Produces flawless moulded parts.

-

Reduces product rejection rate.

-

Enhances surface finish and mechanical properties.

-

Ensures uniform curing and bonding.

-

Saves energy and reduces operational cost.

-

Increases production efficiency.

-

Versatile for multiple industries.

-

Long service life with low maintenance.

-

Improves reliability of finished products.

-

Offers best value for money.

Quality Assurance

Every product undergoes rigorous quality checks and comes with comprehensive warranty coverage.

Frequently Asked Questions

Rubber, plastics, composites, and thermoset materials.

It removes trapped air and gases, ensuring flawless moulding

Automotive, aerospace, medical, and electrical sectors.

Yes, Santec provides customized models as per requirements.

With proper maintenance, it can last 15–20 years.

Santec is based in Cochin, India.

Santec has decades of expertise in industrial machinery.

Yes, Santec supplies machines worldwide.

Yes, they offer installation, training, and service support.

Yes, Santec maintains ready stock for spare parts.

Vacuum compression moulding eliminates air/gas defects, ensuring superior quality compared to normal compression moulding.

Starting price is around ₹7,50,000/- depending on capacity and customization.

Yes, models are available for both low and high production requirements.

With PLC automation, even semi-skilled operators can use it effectively.

Generally, 6–10 weeks depending on specifications.