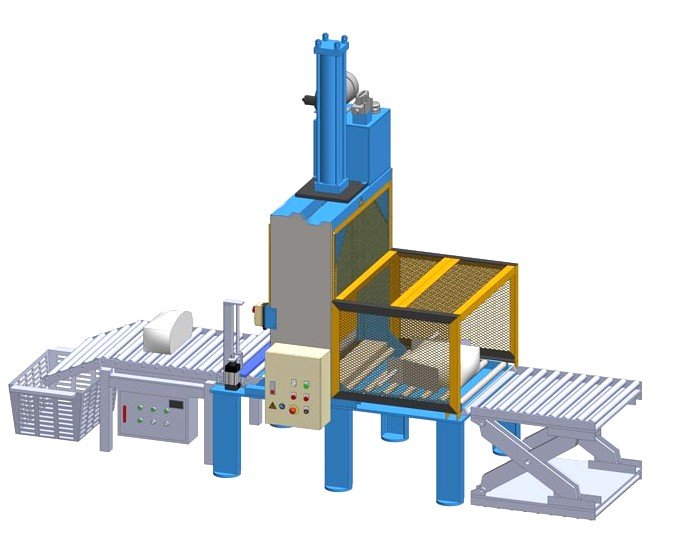

Product Overview – Lab Two Roll Mills (Fixed & Variable Friction Ratio)

Lab Two Roll Mills, with fixed and variable friction ratios, are advanced laboratory machines designed to meet the processing requirements of the polymer, rubber, and plastic industries. These mills are used extensively for mixing, sheeting, plasticizing, and compounding applications. They provide precise control over temperature, friction, and pressure, making them a vital component in R&D laboratories and quality testing units.

Functionality and Applications

Lab Two Roll Mills are highly versatile, enabling uniform dispersion of raw materials, colorants, and fillers into polymers and rubber compounds. The fixed friction ratio ensures consistent mixing operations, while the variable friction ratio allows flexibility in controlling shear rates and blending intensities. This makes the mills ideal for research, formulation development, and small-scale production. Industries such as rubber, plastic, elastomer, and polymer research centers frequently use these machines.

Advanced Features

The mills are built with precision-engineered rolls that are hardened, ground, and dynamically balanced to provide long-lasting performance. Safety features, such as emergency stop, nip guard, and overload protection, enhance operational reliability. Temperature control systems maintain accurate heating and cooling cycles, ensuring the quality of output material. The easy adjustability of the roll gap allows customization of sheet thickness according to requirements.

Quality and Efficiency

With robust construction and advanced friction control, these machines deliver high performance while minimizing material wastage. Their compact design makes them suitable for laboratory environments, while their energy-efficient operation reduces running costs. Additionally, their user-friendly interface ensures smooth operation for both new and experienced technicians.

About Santec Group

Santec Group is a renowned manufacturer and supplier of high-performance rubber and plastic machinery, with a global presence in more than 65 countries. Based in Cochin, India, the company is recognized for delivering innovative, durable, and efficient machines that meet international standards. The Lab Two Roll Mills (Fixed & Variable Friction Ratio) from Santec Group reflect the company’s commitment to quality and precision engineering, making it a trusted choice for industries and research institutions worldwide.

Lab Two Roll Mills Fixed Variable Friction Ratio

Precision Engineered Hydraulic Press Solutions — Powering Performance, Productivity & Perfection.

Available in Cochin

₹450,000.00 / Per piece

Inclusive of all taxes

Established in 1998, Santec Group has grown into a globally trusted leader in hydraulic press manufacturing and industrial automation solutions.

Leading Manufacturer And Supplier in India

- Available in both fixed and variable friction ratio options.

- Precision-ground, hardened, and balanced rolls for durability.

- Adjustable roll gap for customized sheet thickness.

- Integrated heating and cooling system for temperature accuracy.

- Safety systems including nip guard and emergency stop.

Contact Product Information:

Call us for detailed product information, customization options, and bulk pricing.

Product Description

Technical Specifications

| Roll Size | 6” x 12” / 8” x 16” (customizable) |

| Friction Ratio | Fixed (1:1.25) / Variable (1:1.1 to 1:1.5) |

| Roll Material | Hardened & ground alloy steel |

| Drive System | AC motor with VFD control |

| Heating System | Electrical / Oil heating |

| Cooling System | Water circulation |

| Safety Features | Nip guard, emergency stop, overload protection |

| Capacity | 1–5 kg per batch (depending on model) |

| Power Requirement | 7.5–15 HP (depending on size) |

Product Benefits

-

Ensures uniform mixing and dispersion of materials.

-

Suitable for research, testing, and small production runs.

-

Enhances productivity with efficient friction control.

-

Robust and durable construction for long life.

-

Flexible operation with variable speed control.

-

Energy-efficient design reduces operational costs.

-

Compact, lab-friendly structure.

-

Easy to operate and maintain.

-

Reduces material wastage.

-

Trusted brand with international quality standards.

Quality Assurance

Every product undergoes rigorous quality checks and comes with comprehensive warranty coverage.

Frequently Asked Questions

For mixing, compounding, and sheeting of rubber, plastics, and polymers.

Fixed provides constant shear, while variable allows adjustable shear rates.

Yes, it is adjustable for different sheet thicknesses.

Yes, with integrated heating and cooling systems.

Rubber, plastic, elastomer, and polymer research labs.

Based in Cochin, India.

Yes, to over 65 countries worldwide.

Rubber, plastics, polymers, and allied sectors.

Established over three decades ago.

Yes, with global support and spare parts availability.

Around ₹4,50,000/- (approx.).

Yes, ideal for lab testing and pilot-scale operations.

Nip guard, emergency stop, and overload protection.

Between 1–5 kg depending on the model.

Yes, Santec offers customizable roll sizes and features.