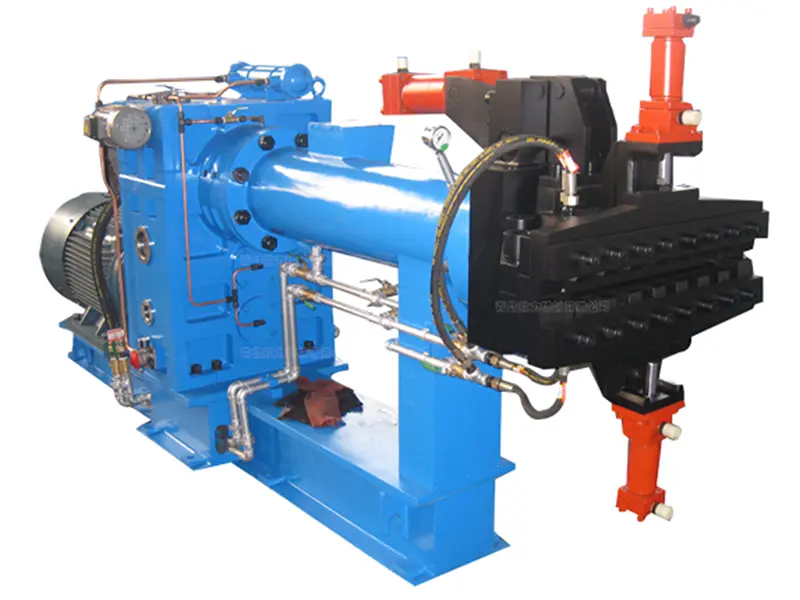

Product Overview of Dispersion Kneaders

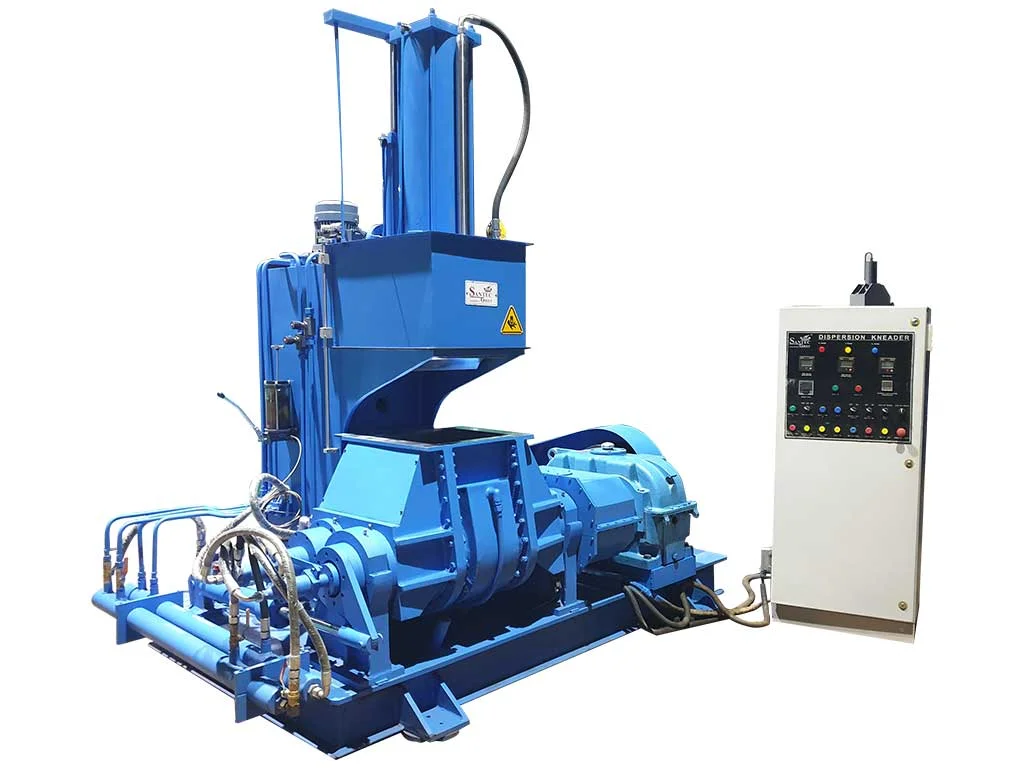

Dispersion Kneaders are highly efficient mixing machines widely used in industries such as rubber, plastics, chemicals, and composites. They are designed to handle tough mixing tasks where precision, consistency, and uniform dispersion of materials are essential. The machine ensures controlled mixing of polymers with additives, fillers, and chemicals, offering superior quality and productivity.

How Dispersion Kneaders Work

Dispersion Kneaders work on the principle of mixing materials through counter-rotating blades within a closed chamber. The blades apply pressure, shear force, and heat to achieve uniform blending. Equipped with advanced temperature controls, these machines help maintain stability during mixing, preventing material degradation and ensuring high-quality output.

Applications of Dispersion Kneaders

Dispersion Kneaders are extensively used in:

* Rubber compounding for automotive, footwear, and industrial applications.

* Plastics manufacturing for blending pigments, stabilizers, and polymers.

* Chemical and pharmaceutical industries require uniform mixing of specialty materials.

* Composites and adhesives for enhanced durability and strength.

Advantages of Using Dispersion Kneaders

These machines offer consistent mixing quality, reduced labor, minimal material wastage, and faster processing cycles. They are energy-efficient, cost-effective, and suitable for both small- and large-scale manufacturing.

About Santecgroup and Its Expertise

Santecgroup is one of the leading manufacturers and suppliers of Dispersion Kneaders, renowned for its innovation and precision engineering. Based in Cochin, the company has built a strong reputation for delivering world-class machinery to diverse industries across India and overseas. With years of expertise, Santecgroup focuses on durability, efficiency, and customer satisfaction. Their Dispersion Kneaders are designed with cutting-edge technology to meet global standards and cater to the growing demands of the rubber and plastic industries.

Dispersion Kneaders

Precision Engineered Hydraulic Press Solutions — Powering Performance, Productivity & Perfection.

Available in Cochin

₹850,000.00 / Per piece

Inclusive of all taxes

Established in 1998, Santec Group has grown into a globally trusted leader in hydraulic press manufacturing and industrial automation solutions.

Leading Manufacturer And Supplier in India

- Robust construction with heavy-duty design.

- Advanced temperature and pressure control.

- High-performance mixing blades.

- Energy-efficient drive systems.

- Easy operation with minimal maintenance.

Contact Product Information:

Call us for detailed product information, customization options, and bulk pricing.

Product Description

Technical Specifications

| Chamber Capacity | 1 to 250 liters (customizable) |

| Motor Power | 20 HP to 500 HP (depending on model) |

| Mixing Rotor Speed | 20–40 RPM |

| Pressure Range | Up to 0.6 MPa |

| Cooling/Heating System | Water/Oil-based. |

| Drive System | AC variable frequency drive. |

| Construction | Heavy-duty steel fabrication. |

Product Benefits

-

Consistent and uniform material dispersion.

-

Increased productivity with shorter mixing cycles.

-

Reduced material wastage.

-

Enhanced product quality and durability.

-

Cost-effective manufacturing solution.

-

Reliable performance for diverse industries.

-

Customizable design for specific needs.

-

Energy savings and reduced operational costs.

-

Long service life with sturdy build.

-

Easy to clean and maintain.

Quality Assurance

Every product undergoes rigorous quality checks and comes with comprehensive warranty coverage.

Frequently Asked Questions

Rubber, plastics, chemicals, pharmaceuticals, and composites.

Capacity ranges from 1 liter to 250 liters.

Yes, advanced heating and cooling systems ensure stable operations.

Yes, it is specially designed for high-viscosity mixing.

With proper maintenance, it lasts over 10–15 years.

Santecgroup is based in Cochin, India.

Yes, they supply machines worldwide.

Yes, they offer installation, training, and maintenance services.

They have decades of experience in machinery manufacturing.

Yes, customized solutions are available as per client needs.

Kneaders are more compact, energy-efficient, and suited for small-to-medium mixing tasks.

Regular lubrication, cleaning, and rotor inspection are required.

Emergency stop, overload protection, and temperature control systems.

Prices start from around ₹8,50,000 and vary based on size and capacity.

Yes, Dispersion Kneaders are designed for single-operator use.