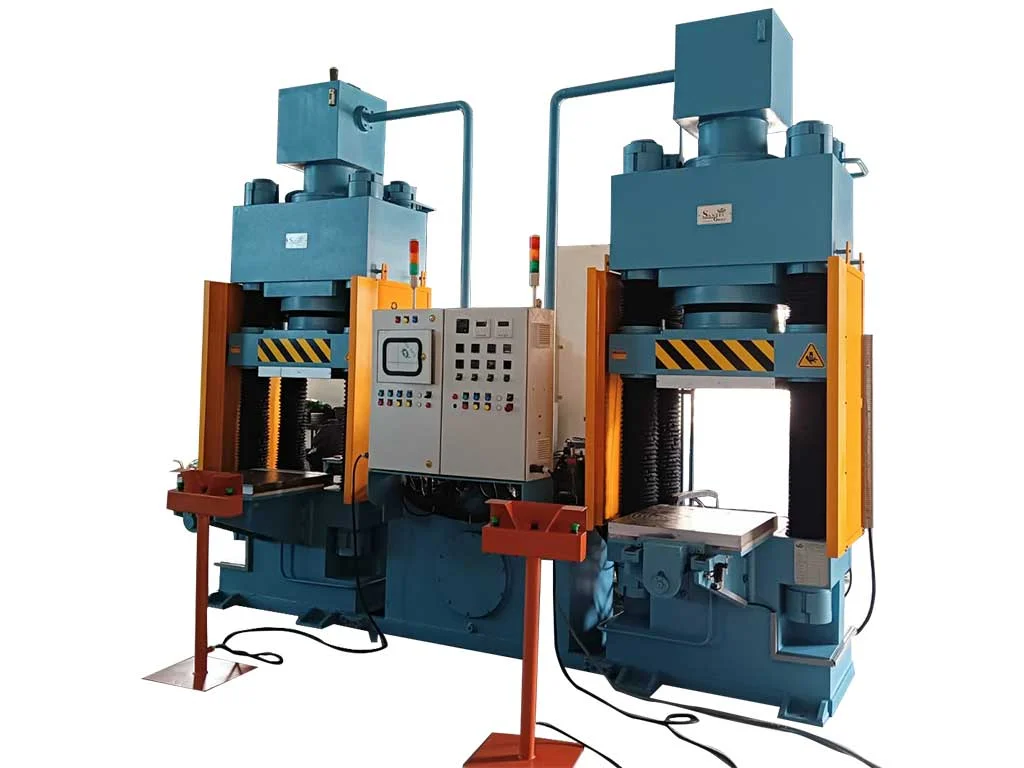

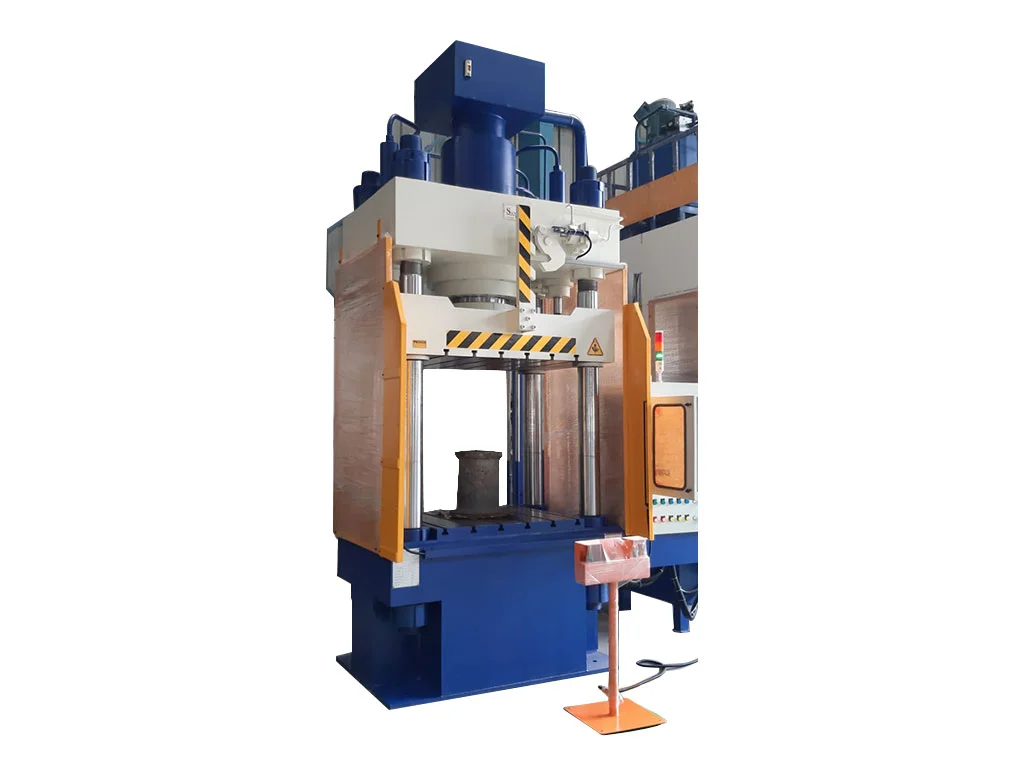

Transfer Molding Presses – Product Overview by Santec Group Corporation

Transfer molding presses are highly efficient machines used in industries such as automotive, electrical, and plastic component manufacturing. These presses are designed to produce high-quality moulded products with precision and consistency. With the growing demand for durable and complex moulded items, transfer molding presses have become a reliable solution for companies seeking to enhance their production capabilities.

How Transfer Molding Presses Work

A transfer molding press uses a closed mould system where preheated material is transferred into cavities to form the desired shape. This process ensures minimal wastage, reduced cycle time, and improved surface finish of components. The system combines the benefits of compression and injection molding, making it suitable for complex shapes and high-strength applications.

Applications in Modern Industries

Transfer molding presses are widely used for producing electrical connectors, rubber seals, automotive parts, and composite products. Industries prefer these machines because of their ability to handle thermoset materials with high dimensional accuracy. Moreover, their energy efficiency and low maintenance needs make them a cost-effective choice for medium to large-scale production.

Advantages of Using Transfer Molding Presses

* Consistent product quality

* Reduced material wastage

* Higher efficiency compared to conventional molding methods

* Ability to mould intricate shapes and fine details

* Suitable for thermosetting plastics and rubber materials

Why Choose Santec Group Corporation?

Santec Group Corporation, based in Calcutta, is one of the leading manufacturers and suppliers of high-performance Transfer Molding Presses in India. With decades of expertise, Santec provides robust, durable, and technologically advanced machinery designed to meet the demands of modern industries. The company is committed to delivering quality equipment at competitive prices, ensuring maximum customer satisfaction. By choosing Santec in Calcutta, businesses not only gain access to premium transfer molding presses but also benefit from after-sales support and trusted manufacturing excellence.

Transfer Molding Presses

Precision Engineered Hydraulic Press Solutions — Powering Performance, Productivity & Perfection.

Available in Calcutta

₹450,000.00 / Per piece

Inclusive of all taxes

Established in 1998, Santec Group has grown into a globally trusted leader in hydraulic press manufacturing and industrial automation solutions.

Leading Manufacturer And Supplier in India

- Heavy-duty steel frame for durability.

- Precision hydraulic system for consistent pressure.

- User-friendly control panel with digital interface.

- High-speed operation with energy efficiency.

- Customizable designs based on client requirements.

Contact Product Information:

Call us for detailed product information, customization options, and bulk pricing.

Product Description

Technical Specifications

| Type | Hydraulic Transfer Molding Press |

| Capacity Range | 30 to 500 Tons |

| Heating Method | Electric/Steam/Hot Oil |

| Platen Size | Customizable (standard 450 x 450 mm to 1200 x 1200 mm) |

| Temperature Control | PID-based digital controller |

| Power Supply | 3 Phase, 415V, 50Hz |

| Cooling System | Water circulation |

| Automation | Semi-automatic / Fully automatic options available |

| Safety Features | Emergency stop, safety guards, overload protection |

Product Benefits

-

Improved production efficiency.

-

Reduced operating costs.

-

Better mould filling and consistency.

-

Long service life of machine components.

-

Low maintenance requirements.

-

Increased safety for operators.

-

Suitable for high-volume production.

-

Superior product finish and accuracy.

-

Energy-efficient hydraulic design.

-

Available at competitive pricing in Calcutta.

Quality Assurance

Every product undergoes rigorous quality checks and comes with comprehensive warranty coverage.

Frequently Asked Questions

It is used for molding rubber, thermosets, and composite materials into precise shapes.

It is mainly designed for thermosets but some models can handle specialized thermoplastics.

Santec offers models ranging from 30 tons to 500 tons.

Yes, the hydraulic system is designed for optimal energy consumption.

With proper maintenance, the press can last over 15–20 years.

The company is based in Calcutta, India.

Santec has decades of experience in designing and supplying industrial presses.

Yes, they provide full support, including installation, training, and maintenance.

Yes, machines can be tailored to specific production needs.

Yes, Santec exports worldwide in addition to supplying across India.

Transfer molding uses preheated material transferred into cavities, while compression molding compresses material directly in the cavity.

Automotive, electrical, aerospace, and plastic manufacturing industries.

Prices start from ₹4,50,000 onwards depending on capacity and features.

Regular lubrication, hydraulic oil checks, and scheduled servicing ensure long life.

Yes, operator training is provided at installation.