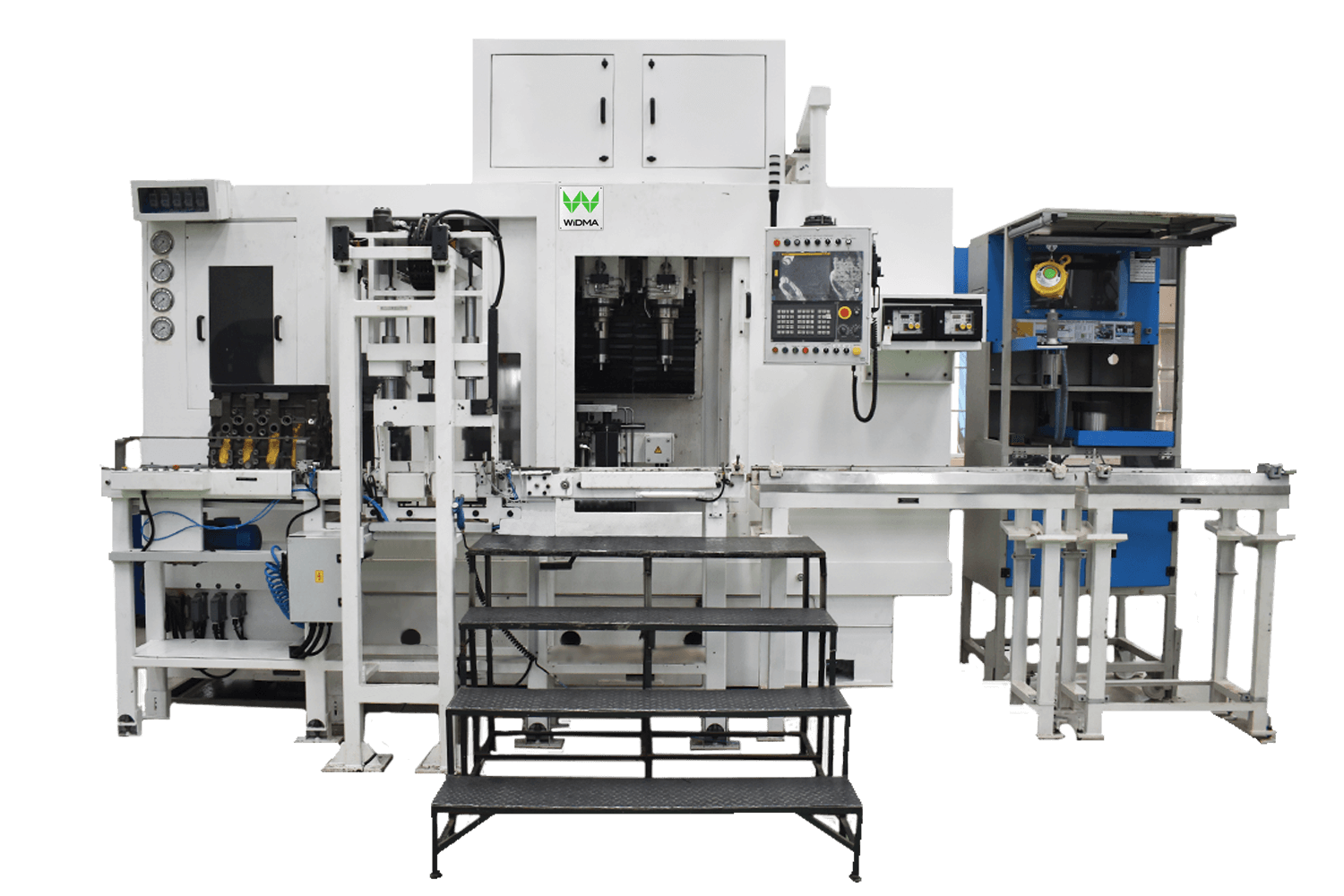

Product Overview of Hydraulic Presses Metal Forming

Introduction to Hydraulic Presses: Metal Forming

Hydraulic presses for metal forming are essential machines widely used in manufacturing industries for shaping, bending, cutting, and pressing different types of metals. Unlike traditional mechanical presses, hydraulic presses use fluid power to generate immense force, providing superior precision and efficiency in operations. These machines have become the backbone of industries such as automotive, aerospace, construction, and heavy engineering.

Applications in Modern Industries

Hydraulic presses are versatile and can perform multiple functions such as stamping, forging, blanking, and sheet metal forming. They are also used for deep drawing applications, enabling manufacturers to produce complex shapes with high accuracy. The ability of hydraulic presses to handle both ferrous and non-ferrous materials makes them an ideal choice for industries requiring durability and adaptability.

Advantages of Hydraulic Technology

Hydraulic press machines deliver consistent force across the entire stroke, ensuring precise shaping of metal components. They consume less energy compared to mechanical presses while maintaining high productivity. Additionally, hydraulic presses require less maintenance and provide greater safety features, making them a cost-effective long-term investment for businesses.

Santecgroup – A Trusted Manufacturer in Calcutta

Santecgroup is one of the leading manufacturers and suppliers of Hydraulic Presses and Metal Forming in Calcutta. With years of expertise and a strong commitment to innovation, the company has built a reputation for delivering world-class machinery to clients across industries. Their hydraulic presses are designed with cutting-edge technology to meet global standards, ensuring accuracy, performance, and reliability. Being based in Calcutta, Santecgroup caters to both local and national clients with efficient after-sales support and customization options.

Hydraulic Presses Metal Forming

Precision Engineered Hydraulic Press Solutions — Powering Performance, Productivity & Perfection.

Available in Calcutta

₹750,000.00 / Per piece

Inclusive of all taxes

Established in 1998, Santec Group has grown into a globally trusted leader in hydraulic press manufacturing and industrial automation solutions.

Leading Manufacturer And Supplier in India

- High precision hydraulic technology

- Sturdy and durable machine structure

- Suitable for multiple forming operations

- Energy-efficient and low maintenance

- Advanced safety controls

Contact Product Information:

Call us for detailed product information, customization options, and bulk pricing.

Product Description

Technical Specifications

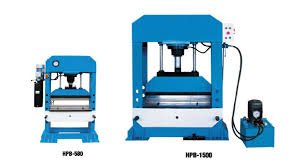

| Capacity | 10 Ton – 5000 Ton |

| Type | Hydraulic press for metal forming |

| Operation | Automatic / Semi-Automatic |

| Control System | PLC-based control panel |

| Stroke Length | 100 mm – 1000 mm (customizable) |

| Bed Size | As per client requirement |

| Frame Type | H-frame / C-frame / Four-column |

| Power Supply | 3 Phase, 415V, 50Hz |

| Safety Features | Overload protection, emergency stop system |

| Material Compatibility | Ferrous and non-ferrous metals |

Product Benefits

-

Delivers consistent pressing force

-

Enhances production efficiency

-

Reduces energy consumption

-

Ensures precise shaping of metal parts

-

Long operational life with low maintenance

-

Supports a wide range of industrial applications

-

Safer operation with built-in safety systems

-

Can be customized for specific requirements

-

Handles complex shapes with ease

-

Increases overall productivity and profitability

Quality Assurance

Every product undergoes rigorous quality checks and comes with comprehensive warranty coverage.

Frequently Asked Questions

For bending, stamping, forging, and shaping metals.

Yes, they are designed for both light and heavy-duty tasks.

No, they are more energy-efficient.

Yes, customization is provided based on client requirements.

Emergency stop, overload protection, and pressure control.

Based in Calcutta, India.

The company has decades of experience in hydraulic machinery manufacturing.

Yes, full installation and after-sales service are provided.

Yes, Santecgroup supplies to both domestic and international markets.

Automotive, aerospace, construction, heavy engineering, and more.

15–20 years with proper maintenance.

From 10 tons to 5000 tons.

Hydraulic presses are more versatile and energy-efficient.

Yes, they can handle aluminum, copper, and other non-ferrous metals.

Starting at ₹7,50,000/- and varies based on capacity and customization.