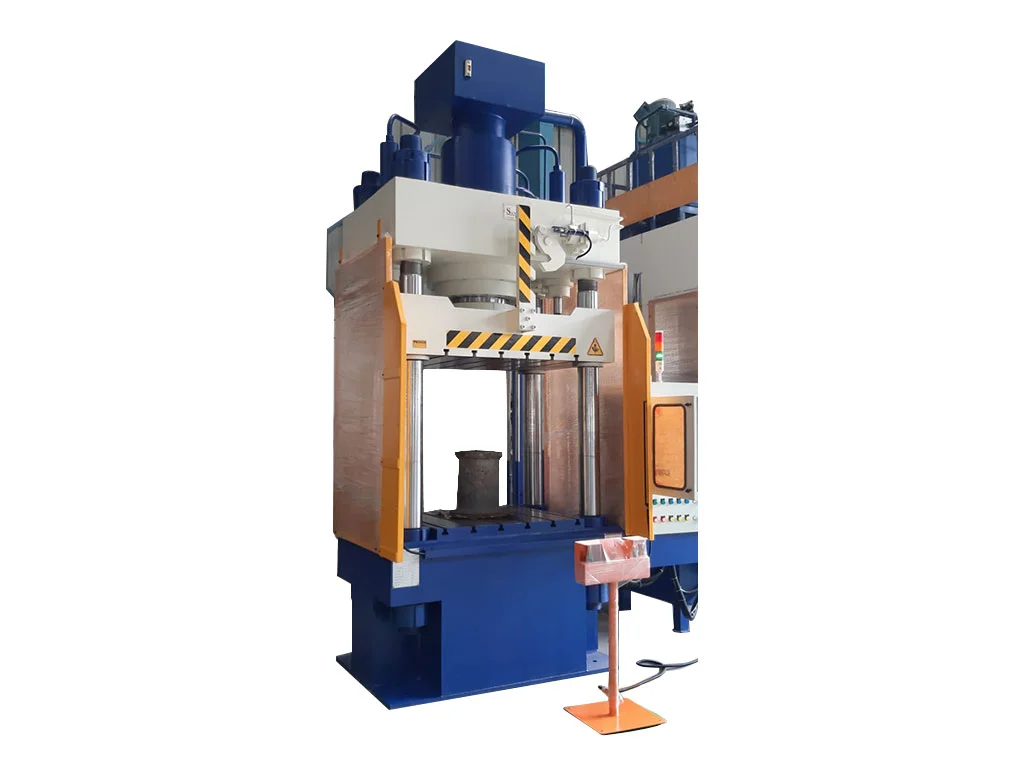

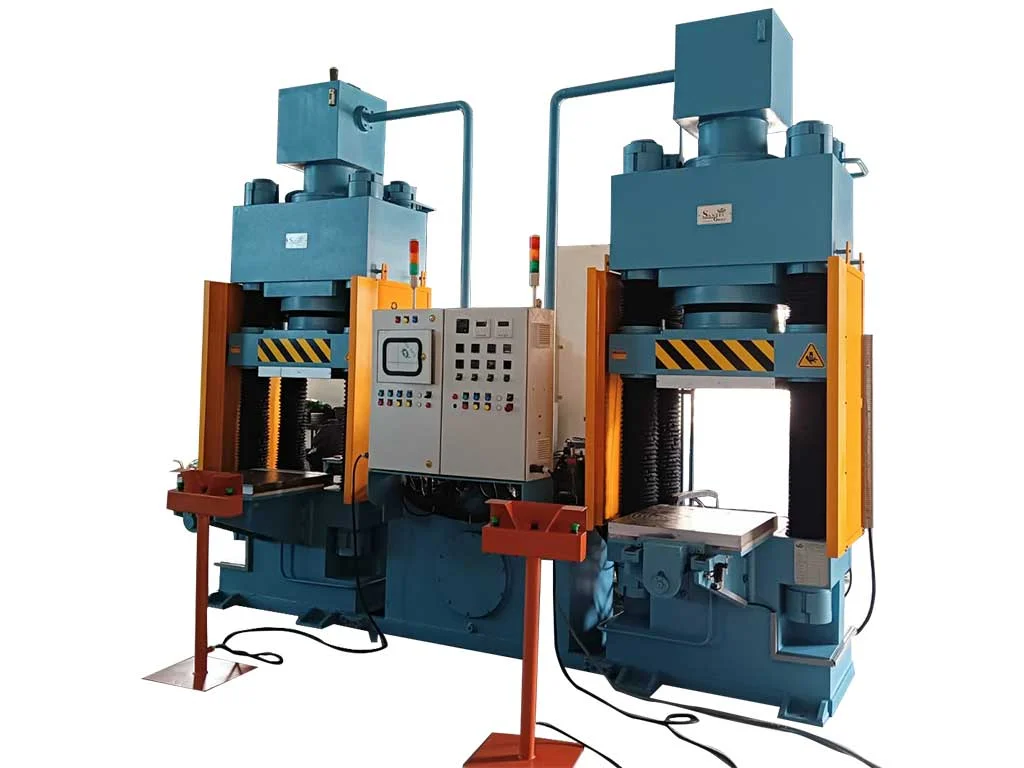

Compression molding presses are essential for industries that work with rubber and composites. They deliver consistent molding quality, high productivity, and excellent durability. Among the various types, Upstroking Compression Molding Presses are widely preferred due to their precise upstroke mechanism, which provides superior clamping force and accuracy during molding operations.

Why Choose an Upstroking Type Press?

In contrast to conventional down-stroking presses, the upstroking press delivers a decisive advantage in mold alignment and equipment longevity. Businesses adopting this mechanism enjoy a competitive edge—products with outstanding finish and reduced maintenance costs. For manufacturers of automotive parts, seals, gaskets, composite sheets, and rubber components, choosing upstroking presses is a strategic investment in quality and efficiency.

Working Principle

The upstroking compression press applies powerful, consistent pressure from beneath the mold. Its hydraulic cylinder ensures an upward push on the platen, tightly compressing raw materials with heat and force. As a result, businesses consistently produce dimensionally accurate, premium-quality molded products that meet and exceed industry expectations.

Applications

* Automotive industry (seals, gaskets, bushings)

* Electrical insulation components

* Aerospace composite parts

* Sports equipment

* Medical rubber products

* Consumer goods

Santec Group Corporation – Manufacturer in Calcutta

Santec Group Corporation is one of the leading manufacturers and suppliers of compression molding presses for rubber and composites – upstroking type in Calcutta. With decades of expertise, advanced infrastructure, and a commitment to innovation, Santec delivers world-class machinery at competitive prices. The company serves industries across India and internationally, ensuring reliable, durable, and high-performance solutions. Customers in Calcutta and surrounding regions can buy directly from the supplier at the best prices.

Compression Molding Presses for Rubber composites Upstroking Type

Precision Engineered Hydraulic Press Solutions — Powering Performance, Productivity & Perfection.

Available in Calcutta

₹750,000.00 / Per piece

Inclusive of all taxes

Established in 1998, Santec Group has grown into a globally trusted leader in hydraulic press manufacturing and industrial automation solutions.

Leading Manufacturer And Supplier in India

- Upstroking hydraulic mechanism for precise pressure application.

- Heavy-duty frame structure for long service life.

- Advanced hydraulic system with PLC control.

- Adjustable temperature and pressure settings.

- Safety interlocks and user-friendly interface.

Contact Product Information:

Call us for detailed product information, customization options, and bulk pricing.

Product Description

Technical Specifications

| Type | Hydraulic Upstroking Compression Molding Press |

| Capacity | 50 – 1000 Tons (customizable) |

| Platen Size | 400 mm x 400 mm to 2000 mm x 2000 mm |

| Stroke Length | Up to 1000 mm |

| Daylight Opening | 200 mm to 1200 mm |

| Heating System | Electrical / Steam / Oil heating options |

| Control Panel | PLC / Manual |

| Power Requirement | 10 HP – 50 HP |

| Construction | Heavy-duty welded steel frame |

| Safety Features | Emergency stop, safety guards, interlocks |

Product Benefits

-

High molding accuracy and superior product finish.

-

Reduced wear and tear of molds.

-

Consistent pressure ensures quality output.

-

Energy-efficient hydraulic system.

-

Easy operation and low maintenance.

-

Suitable for both rubber and composite materials.

-

Extended machine life due to robust construction.

-

Faster cycle times for higher productivity.

-

Wide application across multiple industries.

-

Cost-effective solution for manufacturers.

Quality Assurance

Every product undergoes rigorous quality checks and comes with comprehensive warranty coverage.

Frequently Asked Questions

It is a hydraulic press where the bottom platen moves upward to compress material inside a heated mold.

Rubber, composites, thermosetting plastics, and laminates.

Yes, its robust design supports continuous and large-scale production.

Yes, Santec provides customized capacities, platen sizes, and control options.

Emergency stop, interlocks, safety guards, and overload protection.

Santec Group Corporation is based in Calcutta, India.

The company has decades of experience in manufacturing industrial presses.

Yes, Santec supplies machinery to global markets.

Automotive, aerospace, electrical, consumer goods, and more.

Yes, Santec offers installation, training, and after-sales service.

Upstroking presses move the platen upward, ensuring better alignment and reduced mold wear, while downstroking presses push downward.

Typically between 50 to 200 tons, depending on the product size and material.

Usually 5–15 minutes, depending on material and thickness.

Yes, PLC automation allows semi or fully automated operation.

With proper maintenance, it can last over 15–20 years.