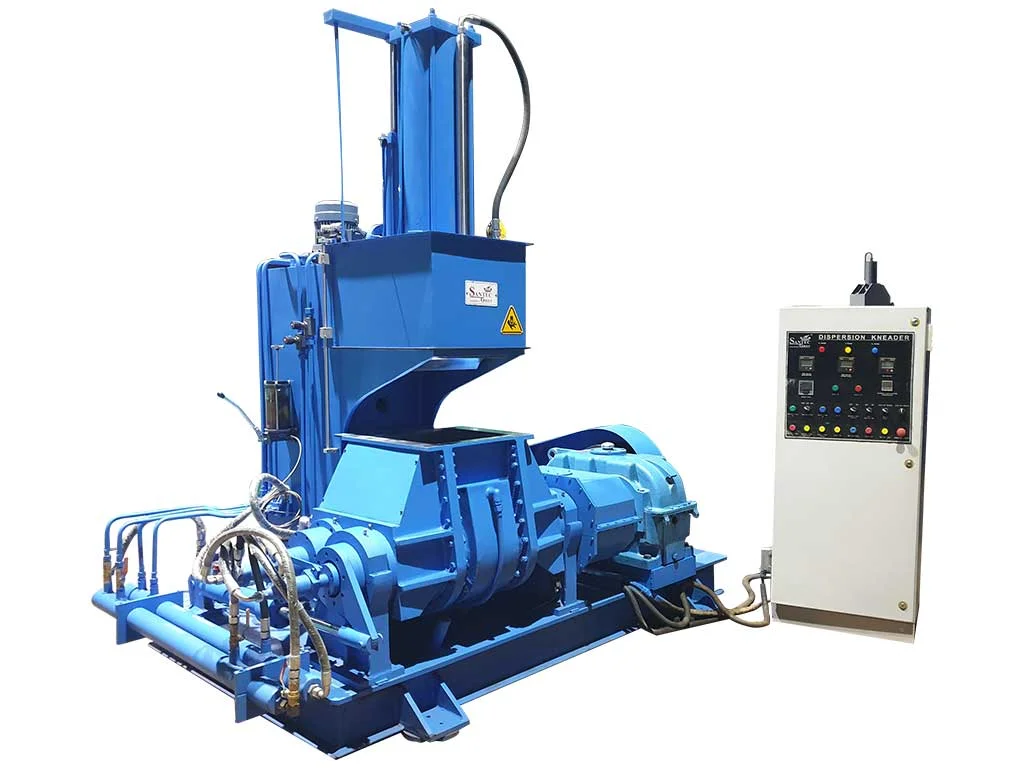

Product Overview of Calendar Machine Line Heating Drums Winders

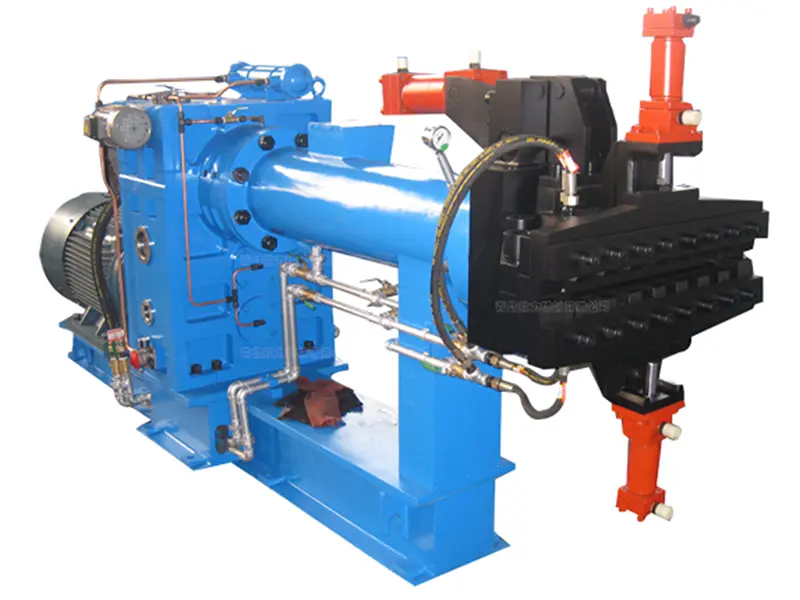

Calender Machine Line Heating Drums Winders are advanced industrial machines widely used in the rubber, plastic, textile, and paper industries for achieving precise sheet formation, uniform thickness, and enhanced surface finish. These machines combine calendering technology with line heating and winding systems to deliver consistent, high-quality outputs. With a focus on accuracy, durability, and efficiency, they play a crucial role in modern manufacturing processes.

Functionality and Applications

The calendering section of the machine ensures controlled thickness and smoothness of materials, while the heating drums maintain consistent temperature for better processing results. The winding unit is designed to handle large rolls without compromising material integrity. These machines are widely applied in the production of rubber sheets, synthetic leather, PVC films, conveyor belts, textiles, and laminates. Their multi-purpose utility makes them a preferred choice for diverse industries.

Features of Heating Drums and Winders

Heating drums play a crucial role in maintaining the right temperature during calendering. They are engineered with precision to deliver uniform heat distribution, which prevents defects in finished products. Winders, on the other hand, ensure proper collection of sheets or films into rolls, minimizing waste and maximizing productivity. Together, they provide seamless operation and consistent quality.

Durability and Efficiency

Built with robust components and high-grade materials, these machines are designed for long-term operation with minimal maintenance. Their advanced automation systems ensure reduced human intervention, saving time and increasing output. Furthermore, the energy-efficient heating system helps lower operational costs without compromising performance.

About Santecgroup – Manufacturer in Calcutta

Santecgroup is a globally recognized manufacturer and supplier of advanced industrial machinery. Based in Calcutta, India, the company has built a strong reputation for delivering innovative, durable, and efficient solutions to industries worldwide. With years of expertise in engineering excellence, Santecgroup specializes in machines such as Calender Machine Lines, Heating Drums, and Winders, ensuring high-quality standards and customer satisfaction. Their commitment to technology-driven solutions has made them a trusted partner for businesses in the rubber, plastic, textile, and allied industries.

Calander Machine Line Heating Drums Winders

Precision Engineered Hydraulic Press Solutions — Powering Performance, Productivity & Perfection.

Available in Calcutta

₹1,200,000.00 / Per piece

Inclusive of all taxes

Established in 1998, Santec Group has grown into a globally trusted leader in hydraulic press manufacturing and industrial automation solutions.

Leading Manufacturer And Supplier in India

- High-precision calendering system with adjustable rollers.

- Energy-efficient heating drums with uniform temperature distribution.

- Automated winding system for smooth roll collection.

- Heavy-duty construction for long-term durability.

- Advanced control panel for easy operation.

Contact Product Information:

Call us for detailed product information, customization options, and bulk pricing.

Product Description

Technical Specifications

| Type | Calender Machine with Heating Drums and Winders |

| Roller Material | Alloy steel / Chilled cast iron |

| Roller Size | Customized (up to 24” diameter) |

| Heating System | Steam / Thermic fluid / Electrical |

| Temperature Range | Up to 250°C |

| Drive System | AC / DC motors with variable speed control |

| Winder Capacity | Up to 1000 mm roll diameter |

| Automation | Semi-automatic / Fully automatic options |

| Power Supply | 220V/380V/440V, 50Hz |

Product Benefits

-

Produces sheets and films with consistent thickness and quality.

-

Reduces manual labor with automated features.

-

Saves energy through efficient heating systems.

-

Ensures higher productivity with minimum downtime.

-

Provides versatile applications across multiple industries.

-

Enhances surface finish and strength of products.

-

Low maintenance requirements for cost-effectiveness.

-

Reliable performance with robust engineering.

-

Optimized for large-scale industrial use.

-

Increases profitability through reduced waste and improved efficiency.

Quality Assurance

Every product undergoes rigorous quality checks and comes with comprehensive warranty coverage.

Frequently Asked Questions

Rubber, plastic, textile, paper, and synthetic leather industries.

Yes, roller sizes are available as per client requirements.

Steam, thermic fluid, and electrical heating systems.

Up to 250°C.

Yes, both semi-automatic and fully automatic models are offered.

The company is based in Calcutta, India.

Yes, they supply to domestic and international markets.

The company has decades of experience in industrial machinery manufacturing.

Rubber, plastic, textile, paper, and allied industries.

Yes, full technical support and after-sales services are provided.

For producing sheets and films with controlled thickness and surface finish.

To maintain uniform temperature and improve sheet quality.

To collect processed sheets/films into rolls efficiently.

Typically 10–15 years with proper maintenance.

Approximately ₹12,00,000/-